Agripellet burners

10 models available with a power range from 25 kW up to 1000 kW:

| Low-medium power | Medium power | Large installations |

| 20 kW | 160 kW | 600 kW |

| 35 kW | 280 kW | 1000 kW |

| 40 kW | 350 kW | |

| 65 kW | ||

| 80 kW |

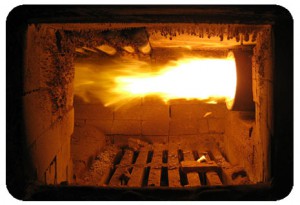

Fast ignition

The flame quickly reaches full power

Traditional biomass systems are characterized by high latency periods: the system takes a long time to reach the desired temperature from the moment we had the initial “request”. Termocabi’s systems are fast and responsive and can quickly reach full power offering a stable and performing flame. The quality of the flame is the result of years of study on the combustion dynamics and it can be observed in the regular shape and the strong radiance.

Agripellet, WASTE becomes a PRODUCT

Biomass from farming waste and repurpose as a ecological biofuel.

Straw pellet

Pellet miscanthus

Rapeseed pellet

Almond shells

Hazelnut shells

Walnut shells

Coconut shells

Grape seeds

These are just some example of agripellets. Each type is characterized by a different chemical composition. In general, agripellet is considered as a low quality biomass due to the high ash content. It tends to be rich in low-melting components that make its application challenging due to the problem of synterizations. These problems can be solved with the application of a burner specially designed for agripellet. Termocabi’s agripellet burner is equipped with an advance pneumatic and mechanical cleanign of the burner.

Agripellet characteristics

Agripellet from grapes shoots

Repurposing of waste from the grape harvesting

Example of a short supply chain: harvesting grapes shoots, peletizing and combustion. Project presented in collaboration of the university “Università Politecnica delle Marche”. (Available only in Italian)